The Mark 2 hand pump must rank – along with the ubiquitous Autorickshaw- as one of the great pieces of design to have originated in India.

Even less celebrated than the pump is its sadly anonymous inventor, a mechanic from Sholapur, Maharashtra. Till 1967 it was known as the Sholapur Pump. It’s specialty was the ability to pump from depths beyond 25′.

Both 1967 and 25′ are significant numbers to deserve our attention. By 1967, India’s traditional simple methods of accessing water from wells, ponds and via the classical S-handled pumps became difficult. 20 years into Independence, a rapidly growing population and urbanisation appear to have lowered the water table. Concentrations in cities and towns made hand drawn water from ponds and wells impractical. Oil engine driven agricultural pumps accelerated water depletion. A culture that had practiced rain-fed or surface irrigation for centuries was running out of water; water by the early sixties, had to be accessed from greater depths.

All mechanical lift pumps can only pump from a maximum depth of 25′. The reason for this is worth learning by every non-technical homesteader. The atmospheric pressure at sea level is 14.7 psi [pounds per square inch] or 1bar. What this means in practical terms is this: if a perfectly friction free pump has a 33′ long suction pipe let into a well, then if pulling the piston up like a syringe creates a perfect vacuum, then atmospheric pressure acting on the well water’s surface will push the water all the way up the 33′ long suction pipe.  That is the theoretical limit. In reality there is always friction and a perfect vacuum is impossible to create. Therefore it is not possible to draw water from depths more than 25′.

That is the theoretical limit. In reality there is always friction and a perfect vacuum is impossible to create. Therefore it is not possible to draw water from depths more than 25′.

In 1967, when India faced widespread drought it appealed to UNICEF for help. And in came a battalion of drilling rigs that could bore down to hundreds of feet.”Between 1970 and 1974, UNICEF shipped in 125 hammer rigs, along with trucks and spare parts. Each of these rigs could drill about 100 boreholes a year — theoretically supplying water to 12,000 villages and about 9 million people” [All quotes are from this reference]What was needed was a rugged hand pump that can lift water from 150′ depths.

The way to lift water from very deep wells is to place the pump within 25′ of its level or better still, submerge it. Electric submersible pumps do just that. The pump and its driving motor are encased in a waterproof tube and lowered into deep well. Power is supplied via a flexible cable and the pump’s discharge is led to the surface via flexible pipes.

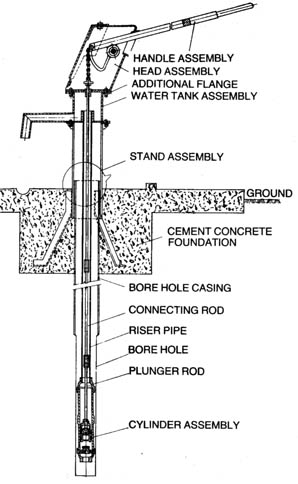

The Sholapur Pump, the forerunner of the Mark 2 pump is a manual, reciprocating equivalent of the electric, rotary, submersible pump. Referring to the illustration at right, the “Cylinder Assembly->” [shown in red in the upper picture], is let down deep into the water in the “Bore Hole Casing->”. A “Connecting Rod->” connects the “Plunger Rod->” of the “Cylinder Assembly->” with the “Handle Assembly->”. The “Stand Assembly->” may be at the surface and the “Cylinder Assembly” as far down as 150 feet. When the handle is operated water is ‘pushed up’ by the cylinder [instead of 'lifted from' as in older pumps]. Water rises to the surface in the “Riser Pipe->” Thus water deep down became accessible due the Sholapur Pump design, and its derivative the modern Mark 2.